Trees for Lurë nursery is located in the village of Fushë Lurë, in the heart of Lurë-Dejës Mt. National Park. It is a critical component of our reforestation efforts and provides sustainable production of the plating material. At 1100 a.m.s.l., it is one of the highest tree nurseries in the Balkan peninsula. It produces 20,000 saplings of Pinus nigra, Pinus peuce and Abies alba (combined) per year.

KEY FACTS

| Year | Species | Seeds | Saplings* | 1 year | 2 year |

|---|---|---|---|---|---|

| 2022 | Pinus nigra | 20,000 | 5,000 | 1,700 | 1,700 |

| 2023 | Pinus nigra | 24,480 | 8,160 | TBD | TBD |

| Abies alba | 20,520 | 6,840 | 3,471 | TBD | |

| Pinus peuce | 60 | 49 | TBD | TBD | |

| 20,049 |

QUICK LINKS

Tree nursery timeline

2023

Valuable experience from the 2022 season allowed us to rethink the approach for the tree nursery and address all major issues we identified in the previous season. We built our first greenhouse, acquired growing trays, planting substrate and expanded the capacity to 15,000 saplings.

Greenhouse

In May 2023, we built our first greenhouse to address the main issue we suffered in 2022: excessive watering as the seedlings were exposed to the rain. The greenhouse allows us to control the amount of water the seedlings receive and regulates the temperature to achieve a more extended vegetation period, which would otherwise be very short.

The greenhouse is 5m x 13m or 65m2, made from a wooden frame and UV-resistant plastic cover. The structure is anchored to the ground with wooden beams, and the plastic cover is attached to the roof and the sides leaving the front and back open for ventilation.

The total capacity of the greenhouse is 20,000—25,000 seedlings depending on the layout of the trays. Next year we will build a second greenhouse to expand the capacity to 50,000 saplings.

Growing trays

In 2022 we used plastic bags to grow our seedlings. Unfortunately, the used bags didn't have enough drainage and were oversized. It is also difficult to lift the bags above the ground to help with drainage and prevent roots from growing into the ground.

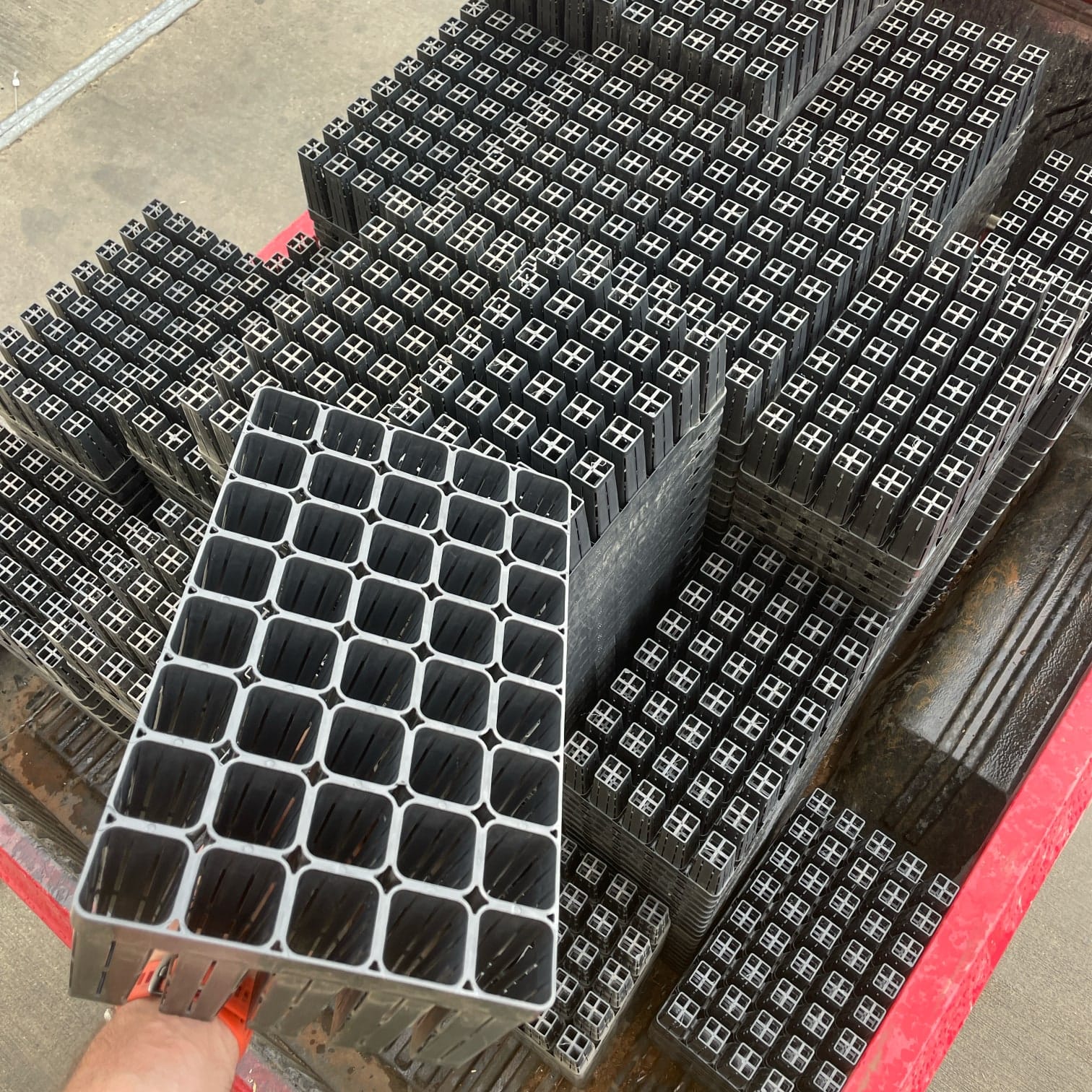

To address these issues, we decided to grow our seedlings in special growing trays designed for growing conifers' saplings. We are using two sizes of growing trays from the Swedish company BCC which specializes in nursery technologies.

For the 1st year seedlings, we use BCC HIKO V120SS growing trays to achieve 15,000 capacity. Seedlings are replanted after the 1st year into BCC HIKO V256 trays and grow for another 1—2 years.

Planting substrate

In 2022 we used a mixture of the soil from the planting area with nutrient-rich soil from the local field. This mixture could have been better as it was too dense, had the wrong pH values, and contained weeds and fungi, which affected the seedlings.

We changed our planting medium from the locally sourced soil to a special peat moss planting substrate for conifers with a correct pH value of 3.8—4.5 and mixed it with Perlite. This mixture is light, allows good drainage, and is free from weeds and fungi. It also does not contain any fertilizers as other substrates, which enables us to control the amount of nutrients the seedlings receive.

2022

In 2022 we established a simple tree nursery to test the viability of producing our saplings in the Fushë Lurë with the target of 5,000 saplings of Pinus nigra.

Experimental nursery

When we started the tree nursery in the 2022 project, we had very little knowledge within the team about running the nursery or growing seedlings and saplings. After all, it looks effortless when visiting other nurseries with vast numbers of healthy seedlings and saplings.

Well... when something looks simple, it's usually because someone dedicated a lot of time to make it run smoothly.

We started with the idea that we would grow our saplings in the most natural way possible, without greenhouse, fungicides or artificial fertilizers. While this sounds like a good idea, the reality of harsh high-altitude weather and the resulting short vegetation period makes this approach quite tricky.

We planted 5000 bags, four seeds per bag, to compensate for the natural loss as some seeds will not germinate. The soil we used to plant the seeds was a mix of the soil from the planting area and nutrient-rich soil from the field near the nursery. We placed our bags on the ground without any cover and did not use any fungicides or fertilizers.

The first two months were quite successful, the seeds germinated, and the seedlings grew. However, after two months, we started to see the first signs of root rot. We tried to save the seedlings by applying fungicide, but it was too late. The root rot spread quickly, and we lost most of the seedlings.

The 1,700 surviving seedlings kept growing throughout 2022, and almost all survived the harsh winter. In Spring 2023, they started 2nd vegetation period ending in Autumn when they will be planted.

Lessons learned

Oh boy..., it's learning by doing!

The main issue with the 2022 tree nursery was the lack of a greenhouse, which left seedlings exposed to the rain without any means to regulate the amount of water. These conditions caused root rot and fungi infestation, resulting in the loss of 70% of the seedlings.

The other issue was the growing bags we used to plant the seeds. The bags were too big and lacked drainage, which, combined with the lack of a greenhouse, caused the root rot. The bags were also placed on the ground, contributing to poor drainage.

The soil we used to plant the seeds could have been better as we used what was available locally. The resulting mixture was too dense and had the wrong pH value. It also contained weeds, fungi and other parasites, which, when left untreated, caused the loss of 70% of the seedlings.

Why do we need a tree nursery?

Production of our planting material is essential for our reforestation efforts in the highest protected areas of the national park due to the requirements on the quality of the saplings.

Planting material requirements

Lurë-Dejës Mt. National Park is a protected area under the management of Agjencia Kombëtare e Zonave të Mbrojtura (AKZM). The AKZM sets requirements for the planting material allowed during planting operations within the national park.

These requirements are based on the planting area's location location within three protected zones. The zones above 1 500 a.s.m.l. fall within the highest protected zone, lower altitudes in the remaining two. We aim to plant in the most protected area (most destroyed) with the strictest requirements.

Conifer species allowed to be planted in the national park are Pinus nigra, Pinus Peuce and Abies alba, and as for deciduous species, it is Fagus silvatica.

The saplings are required to be:

- one of the allowed species

- produced from the local seeds

- grown at a similar altitude as the planting area

Economical advantages

Apart from the regulatory requirements, our production of the samplings brings significant economic advantages. These financial savings may not be evident at lower volumes (< 5,000 saplings), but as we scale up our reforestation to more than 10,000 saplings per year, the savings become quickly significant.

The cost per sapling grown in the nursery is currently €0.92, comparable with commercial offers from other nurseries before the discount. Our costs are currently higher than the discounted price of €0.67 we pay for the sapling. The higher cost is due to the investments we had to make to establish the nursery. These investments will be fully depreciated within three years, and the cost per sapling will drop significantly.

Another significant saving is the saplings' transportation cost from the lowlands nurseries to the planting areas in the Lure-Dejes Mt. National Park. Producing the saplings in the nursery cuts the buying and transportation costs, which are much more significant for larger numbers of saplings.

Tree spices and how we grow them?

In the table below, you can find details about the species we grow in the nursery. We focus on the combination of species we can use in the high-altitude reforestation projects in Albania.

| Spices | Stratification | In nursery | Process1 |

|---|---|---|---|

| Black pine / Pinus nigra | 21—28 days | 2 years | fv1+fv1 |

| Macedonian pine / Pinus peuce | 180—210 days | 2 years | fv1+fv1 |

| Silver fir / Abies alba | 42—56 days | 3 years | fv1+fv2 |

v - above ground

+ - replanting into larger container

number - number of years

Growing a healthy sapling

- Seed collection

- Everything starts with collecting seeds from the adult trees in the national park. Each species has a different time when the pine cones are collected. Once the cones are collected, they are dried and placed in a warm environment to open up and release the seeds.

- Seed cleaning & processing

- Seeds must be cleaned of pine cone debris, seed wings and other impurities. After cleaning, the seeds are processed to separate dead seeds from viable ones.

- Seed stratification & germination

- Stratification is the process of exposing the seeds to a cold and moist environment to simulate winter conditions. This process is required to break the seed dormancy. The processed seeds are placed in the stratification boxes and stored in the fridge for the necessary period of time. The seeds are monitored to maintain the correct moisture level and temperature.

- Planting seeds into containers

- Once the seeds are stratified and begin to germinate, they are sown into BCC HIKO V120SS growing containers filled with the planting substrate. Seeds don't germinate at the same time despite the stratification. We plant the early seeds separately from the main batch.

- Seedling: 1st year in the nursery

-

The containers are placed in our greenhouse, where the seedlings are grown for the first year. The greenhouse is essential for the seedlings as the weather in Lurë provides a very short vegetation period compared to the nurseries in the lowlands. A greenhouse protects the seedlings from rain, winds and hail and allows us to control the watering.

The first two months are crucial as the seedlings are susceptible to fungi and root rot. At this stage, we apply a low dosage of fungicide to protect the seedlings. In the 2nd half of the vegetation period, we use mild bio-stimulants to boost the growth. - Sapling: 2nd/3rd year in the nursery

- After the first year, the seedlings are replanted into larger BCC HIKO V256 growing trays, where they grow in the greenhouse into saplings for another 1—2 years, depending on the species. The saplings are watered and fertilized regularly.

Ecology and sustainability

Standard practice in Albanian nurseries is to grow the saplings in plastic bags or growing containers/trays suitable for single use. This practice generates a lot of plastic waste which is not recycled in Albania and ends up in landfills. The same problem applies when buying the saplings from the nurseries as they are sold in the plastic bags they were grown in.

For example, for our 1st year 5,000 seedlings, we required 35kg of plastic growing bags which can't be reused. The 2022 batch of 10,000 trees bought from the nursery generated more than 100kg of plastic waste.

We decided to use the growing trays designed to last for many years. Our containers from the Swedish company BCC are made from recycled plastic and rated for 10 years of use.

These trays allow us to significantly reduce plastic waste and the cost per sapling in the future.